MIM Chine

AS Industries offers you to manufacture your parts in MIM (Metal Injection Molding). This process, suitable for small precision parts, will allow you to produce parts and benefit from exceptional properties on the resistance and wear of metals.

Metal powder injection molding will offer you a wide range of design possibilities to shape complex parts suitable for medium and large series while reducing machining rework.

Cette technologie adaptée pour la petite, moyenne et grande série vous permettra de réduire les reprises d’usinage, les frais de finition ainsi que le recours à des techniques de montage/assemblage coûteuses.

Our MIM process is suitable for various fields of application such as watch / jewelry, eyewear or medical with surgical instruments and other sectors such as telephony and IT etc.

TECHNICAL ASPECTS OF MIM :

- Small, lightweight parts weighing from 0,3g à 150g

- Components with a wall thickness of 0.2 mm.

- Surface finish: Ra < 1.5 µm

- Possibility of making small and large bores, cross bores

- Possibility of internal and external threads, undercuts and serrations

- 25% to 65% savings compared to standard processes

- Significant reduction in manufacturing costs for complex components

- Same mechanical strength as conventionally manufactured parts

Conventional

OUR RANGE OF MATERIALS:

The metals used are generally low-alloy steels, stainless steels and tool steels.

Our metals :

- Irons

- Iron alloys

- Stainless steel

*Other materials on request.

Our metals

- Irons

- Iron Alloys

- Inox

*Autres matières sur demande.

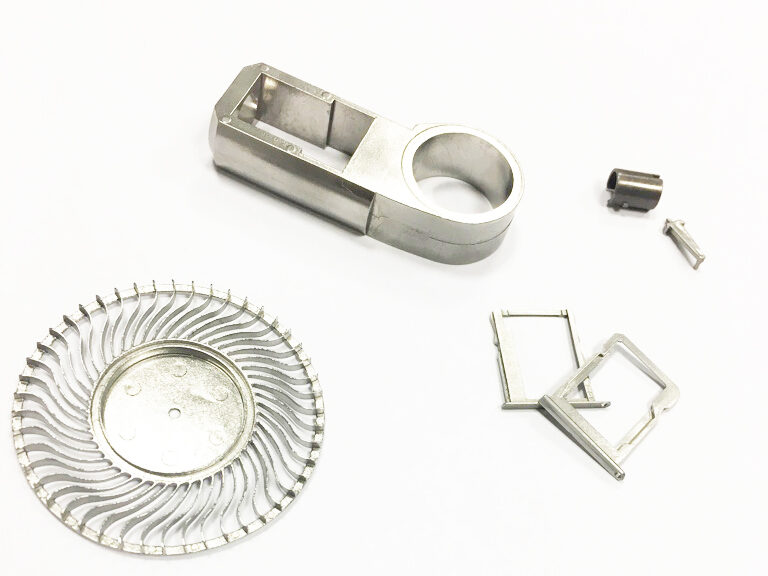

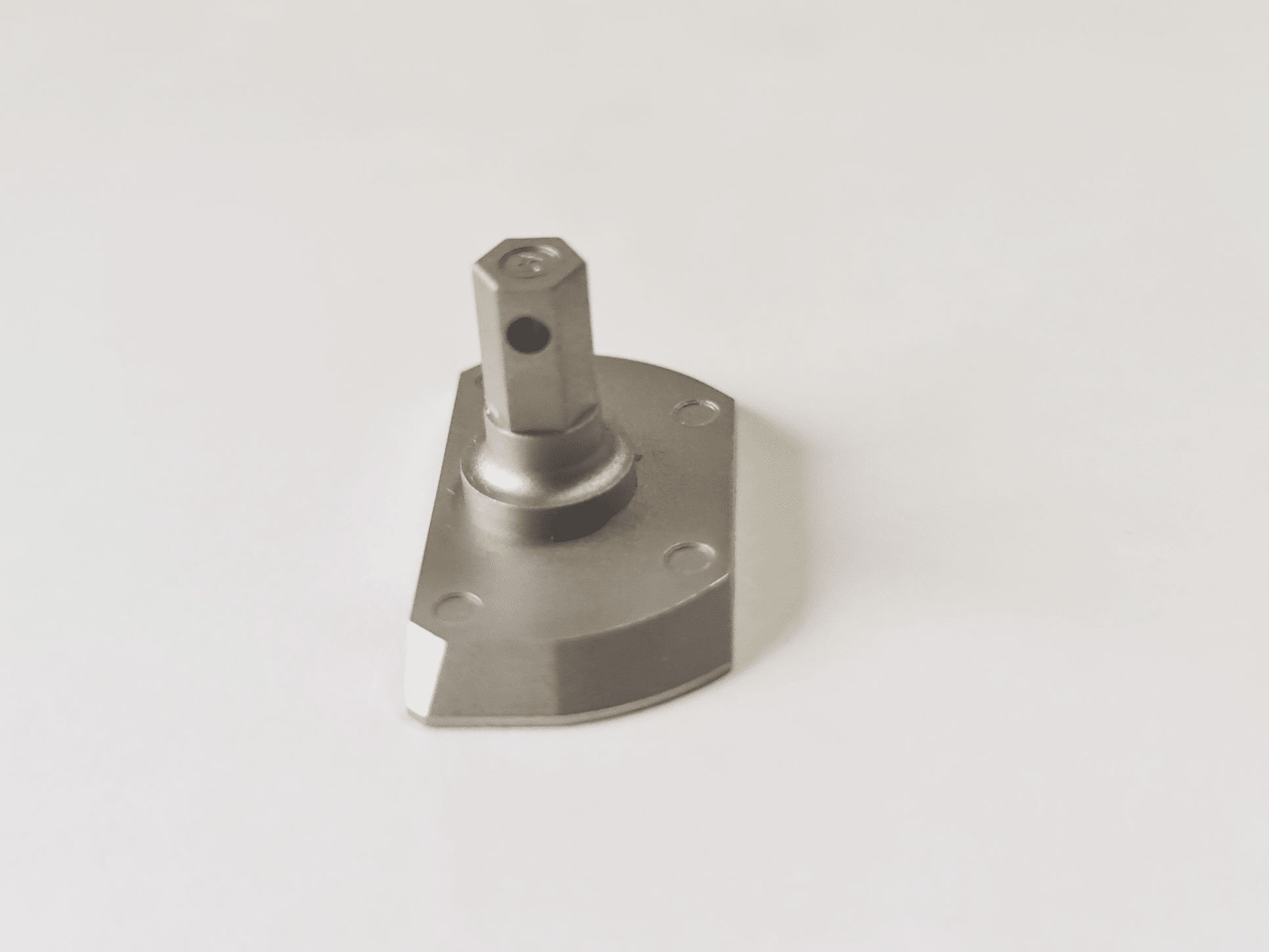

OUR REALISATIONS:

MEET OUR LABORATORY TO YOUR REQUIREMENTS:

We can also guarantee the conformity of your parts thanks to our quality controls carried out in our control laboratory based in Bordeaux. On request, we can provide you a test certificate and a material certificate.